Talk to us

08071793296

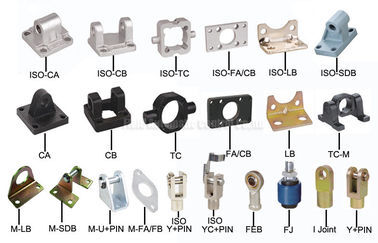

| Mounting Type | Description | Typical Use |

|---|---|---|

| Foot Mount (MS / FA / FB) | Brackets bolted to the cylinder body sides or bottom | Stationary base mounting |

| Front Flange (FF) | Flange plate on front of cylinder | Heavy load applications |

| Rear Flange (RF) | Flange plate on rear side of cylinder | Axial mounting on a frame |

| Front Trunnion (TF) | Pivot pin at front end | For pivoting motion around front end |

| Rear Trunnion (TR) | Pivot pin at rear end | For pivoting motion around rear end |

| Double Trunnion (DT) | Trunnions on both ends | Central pivot mounting |

| Clevis Mount (LB / CA) | Fork-type clevis on rear end | Allows swinging motion |

| Eye Bracket (CB) | Round eye on rear end | Pivoting applications |

| Rod Eye (I / Y) | Eye fitted on piston rod end | Pivoting load connection |

| Rod Clevis (U / CU) | U-fork on piston rod end | For linkage connections |

| Spherical Rod End (SR / P) | Ball joint type rod end | Misalignment tolerance |

| Intermediate Trunnion (IT) | Trunnion mounted in center of barrel | Balanced pivot mounting |

| Swivel Mount (SM) | Bearing type that allows angular movement | For dynamic angle movements |

| Foot + Clevis Combination | Both fixed and pivot ends combined | Mixed applications |

Material: Carbon Steel / Stainless Steel / Zinc Plated Steel

Mounting Accuracy: 0.1 mm

Load Capacity: As per cylinder bore size

Mounting Accessories: Bolts, pins, clips, retaining rings

Applicable Cylinders: All standard ISO/VDMA type cylinders

Interchangeability: Compatible with ISO/ SMC / Festo / Parker type cylinders

Pneumatic cylinder mounting

Cylinder foot mount

Cylinder flange mount

Cylinder clevis bracket

Cylinder trunnion mount

Rod eye end

Rod clevis end

Pivot cylinder mount

Cylinder mounting accessories

ISO cylinder mounting types

Price:

Price 650.0 INR / Piece

Minimum Order Quantity : 15 Pieces

Color : White

Power : Pneumatic

Usage : Industrial

Material : Stainless Steel

Price 1250.0 INR / Piece

Minimum Order Quantity : 15 Pieces

Color : Sliver

Power : Pneumatic

Usage : Industrial

Material : Steel

Price 1000 INR / Piece

Minimum Order Quantity : 15 Pieces

Color : White

Power : Pneumatic

Usage : Industrial

Material : Steel

Price 700 INR / Piece

Minimum Order Quantity : 50 Pieces

Color : White

Power : Pneumatic

Usage : Industrial

Material : Steel